Cast Iron square penstock gate

FYL is a factory which focused on manufacturing different types of cast iron square penstock gate in China, including cast iron square penstock gate, L type single girder gantry crane and so on. Our company available to provide OEM product according to clients require. We welcome both new and old customers, hoping to become your long-term partner in China.

Send Inquiry

Product Introduction

The cast iron square penstock gate manufactured and supplied by FYL mainly has these components: transmission device, bracket, screw rod, gate, door frame, wedge, and others.

As a useful product, the gate can be used in pipeline and intersection inspection wells, mud and sand pools, sewage channels, pump station water inlets, clean water pools and other water treatment structures to intercept, dredge or adjust water levels. At the same time, it can also be used in agricultural irrigation and drainage or other water conservancy facilities, with a wide range of uses.

The gate can be used with manual, electric and other hoists.

Product Features

1. Material and structure: The raw materials of cast iron square penstock gate are high-quality cast iron or ductile iron. The guide rails are set in a bilaterally symmetrical form and connected to the ends of the door frame on both sides through stainless steel bolt locating pins. In addition, for small and medium-sized gates, the guide rails can be integrated with the door frame, which is very convenient. In terms of design, the length of the guide rail is usually one-half to one-third of the full opening height of the gate, making the structure stable, strong, rigid, and with good wear resistance and corrosion resistance, and excellent pressure bearing capacity to meet your needs.

2. Sealing performance: The sealing performance of the product is achieved through a wedge-tightening device and copper strips or rubber as sealing materials. The raw materials are precision machined and ground to further ensure the sealing effect.

3. Usage and function: The gate opening and closing machine has various operation modes, which can be supported by manpower, motors or starting devices. During the overall use process, the hydraulic mechanism drives the components of the transmission device to operate. After precise design and coordination, the vertical lifting and lowering movement of the gate shaft is completed, and finally the gate is opened and closed, which plays the role of opening and closing water, water supply, or water level regulation.

Notes for Installation

Regardless of the type of cast iron square penstock gate, as a professional manufacturer, we do not recommend that you install the door frame and the door body separately, and recommend the whole installation. Separate installation can easily cause deformation of the door frame, which in turn affects the use effect, and causes leakage or non-operation of the hoist.

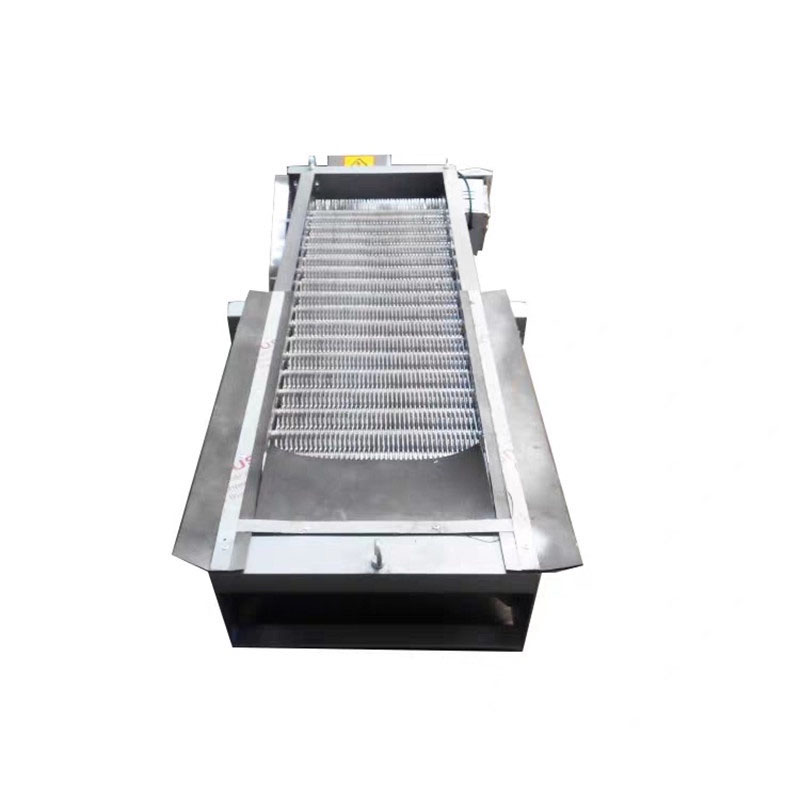

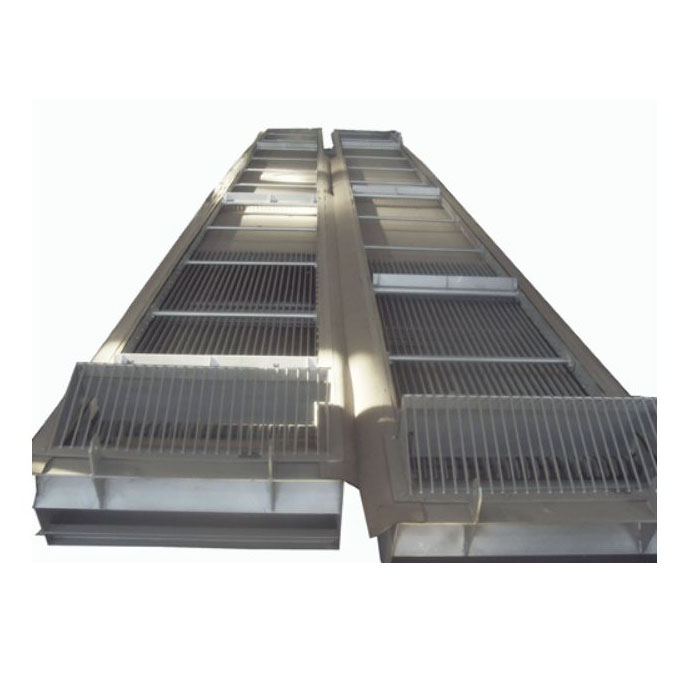

Sample Structure and Photos

Actual size and structure depends on customer request

Square Type Penstock Gate

|

Type |

Hole Size W×H (m) |

A |

B |

C1 |

F |

S1 |

C |

H |

S |

Ø1 |

Hoist(1) |

Water level(m) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

DY300×300 |

300×300 |

300 |

300 |

540 |

360 |

60 |

420 |

720 |

150 |

12 |

0.5 |

4 |

|

DY400×400 |

400×400 |

400 |

400 |

640 |

460 |

60 |

520 |

920 |

200 |

14 |

0.5 |

4 |

|

DY500×500 |

500×500 |

500 |

500 |

740 |

560 |

60 |

620 |

1120 |

250 |

14 |

1 |

4 |

|

DY600×600 |

600×600 |

600 |

600 |

840 |

660 |

60 |

720 |

1320 |

300 |

14 |

1 |

4 |

|

DY800×800 |

800×800 |

800 |

800 |

1060 |

875 |

75 |

940 |

1750 |

400 |

14 |

2 |

6 |

|

DY1000×800 |

1000×800 |

1000 |

800 |

1270 |

875 |

75 |

1150 |

1750 |

400 |

16 |

2 |

6 |

|

DY1200×300 |

1200×300 |

1200 |

300 |

1460 |

360 |

60 |

1340 |

720 |

150 |

18 |

2 |

6 |

|

DY1400×500 |

1400×500 |

1400 |

500 |

1660 |

560 |

60 |

1540 |

1120 |

250 |

18 |

3 |

6 |

|

DY1600×500 |

1600×500 |

1600 |

500 |

1860 |

560 |

60 |

1740 |

1120 |

250 |

20 |

3 |

6 |

|

DY1800×500 |

1800×500 |

1800 |

500 |

2100 |

560 |

60 |

1980 |

1120 |

250 |

20 |

3 |

6 |

|

DY2000×500 |

2000×500 |

2000 |

500 |

2300 |

560 |

60 |

2180 |

1120 |

250 |

20 |

3 |

6 |