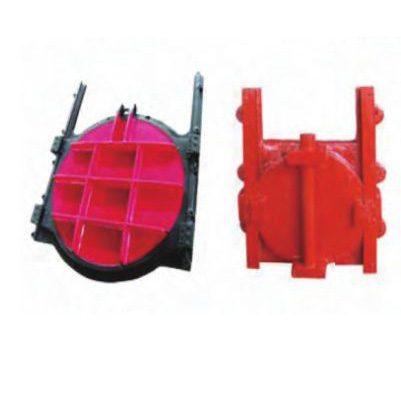

Cast Iron Round And Square Penstock Gate

FYL is a professional cast iron round and square penstock gate manufacturer and supplier in China. Our team has years of industry experience, and support customized production. At the same time, we will also offer you comprehensive service and after-sale service, welcome to contact with us now.

Send Inquiry

Product Introduction

Cast iron round and square penstock gate is a gate that can intercept, dredge, or adjust water levels. It can be used with different hoists including manual and electric. This product can play a role in various water treatment structures, water conservancy facilities or agricultural irrigation scenes. Its structural components include transmission devices, brackets, screw rods, gates, door frames, wedges, etc.

Product Features

Material: high-quality gray cast iron or ductile iron.

Guide rail: symmetrical arrangement, stainless steel bolt locating pins connected to the ends of the door frame on both sides. If you encounter a small or medium-sized valve, you can connect it together. The length is one-half to one-third of the full opening height of the door.

Sealing: Made of precision-processed copper strips or rubber as raw materials, wedging is achieved, and the sealing is good.

Use: manpower, electric motor or pneumatic device can be used. The hydraulic mechanism drives the transmission device to realize the movement of the gate shaft and ultimately guide the gate to open and close.

Function: water supply or water level regulation.

Advantages: cast iron round and square penstock gate has high structural strength, good rigidity, wear resistance, corrosion resistance, and excellent pressure bearing capacity.

Install Notes

For cast iron round and square penstock gate, especially small specifications such as DN200mm, DN300mm and DN400mm, the whole installation method is usually adopted, rather than separating the door frame from the door body and installing them one by one.

This suggestion is based on rigorous technical considerations: the separate installation process of the door frame and the door body has a high risk of causing the door frame structure to deform. Such deformation may not only cause the gate sealing performance to deteriorate, leading to water leakage, but may also seriously interfere with the normal operation of the hoist, thereby affecting the stability and safety of the entire water conservancy system.

Round Type Penstock

Actual size and structure depends on customer request

Ø200-Ø1200 Round Type Size

|

Type |

Size D |

Install Size(mm) |

Operation(1) |

Water level(m) |

||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

A |

B |

D1 |

H |

F |

n×d |

Ø1 |

||||

|

MXY-200 |

200 |

382 |

210 |

230 |

450 |

100 |

4×M16 |

18 |

0.5 |

4 |

|

MXY-250 |

250 |

426 |

250 |

280 |

550 |

100 |

4×M18 |

20 |

0.5 |

4 |

|

MXY-300 |

300 |

494 |

300 |

330 |

650 |

100 |

4×M20 |

22 |

0.5 |

4 |

|

MXY-400 |

400 |

586 |

400 |

430 |

800 |

100 |

4×M22 |

24 |

1 |

4 |

|

MXY-450 |

450 |

642 |

450 |

482 |

900 |

110 |

4×M22 |

24 |

1 |

4 |

|

MXY-500 |

500 |

706 |

500 |

534 |

1000 |

110 |

4×M24 |

28 |

1 |

4 |

|

MXY-600 |

600 |

826 |

600 |

636 |

1200 |

120 |

4×M24 |

28 |

2 |

6 |

|

MXY-700 |

700 |

940 |

700 |

738 |

1400 |

120 |

4×M24 |

28 |

2 |

6 |

|

MXY-800 |

800 |

1040 |

800 |

840 |

1600 |

120 |

4×M27 |

32 |

2 |

6 |

|

MXY-900 |

900 |

1290 |

900 |

950 |

1800 |

120 |

4×M27 |

32 |

3 |

6 |

|

MXY-1000 |

1000 |

1380 |

1000 |

1050 |

2000 |

140 |

4×M30 |

35 |

3 |

6 |

|

MXY-1200 |

1200 |

1600 |

1200 |

1250 |

2400 |

140 |

4×M36 |

42 |

3 |

6 |

Ø1400-Ø2000 Round Type Size

|

Type |

Size D |

Install Size(mm) |

Operation(1) |

Water Level(m) |

|||||

|---|---|---|---|---|---|---|---|---|---|

|

B |

D1 |

F |

Ød |

H |

n×d |

||||

|

MXY-1400 |

1400 |

1570 |

1400 |

80 |

28 |

2300 |

4×525 |

3 |

6 |

|

MXY-1500 |

1500 |

1680 |

1540 |

100 |

28 |

2500 |

4×575 |

5 |

6 |

|

MXY-1600 |

1600 |

1780 |

1640 |

100 |

28 |

2600 |

4×600 |

5 |

6 |

|

MXY-1700 |

1700 |

1880 |

1740 |

100 |

28 |

2800 |

4×650 |

5 |

6 |

|

MXY-1800 |

1800 |

1980 |

1840 |

100 |

28 |

2600 |

4×675 |

8 |

6 |

|

MXY-1900 |

1900 |

2100 |

1940 |

120 |

28 |

3100 |

4×725 |

8 |

6 |

|

MXY-2000 |

2000 |

2200 |

2040 |

120 |

28 |

3200 |

4×750 |

8 |

6 |