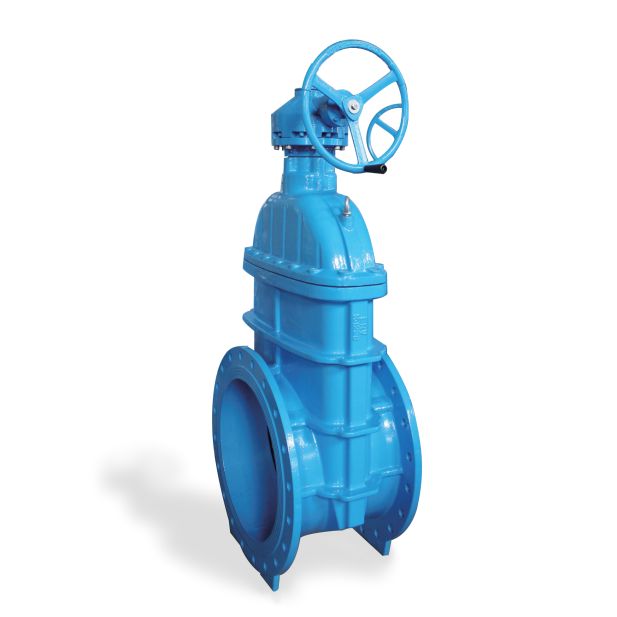

Rising Stem Resilient Seat Gate Valve

FYL is a water conservancy machinery and equipment factory located in Tianjin, China. The factory has rich experience in valve production, and rising stem resilient seat gate valve is one of our main products. We can produce OEM products and also support customized production services, providing personalized but equally considerate services and products for different customers.

Send Inquiry

FYL's rising stem resilient seat gate valve is a good and well-recognized product, mainly used to connect or cut off the medium in the pipeline.

This gate valve is suitable for a wide range of pressures, temperatures, and calibers, especially for medium and large diameter pipelines. It can provide good sealing in the face of various media and stress environments without restrictions. The valve is easy to operate, reduces time and manpower and material costs in maintenance, and has a long service life.

The rising stem resilient seat gate valve is suitable for a wide range of industries, including drainage, gas, electricity, metallurgy, petroleum, chemical industry, textile, urban construction, etc. It can be used to open and close steam, water and oil medium pipelines.

Product Feature

1. Overall rubber coating: The valve core of the rising stem resilient seat gate valve adopts the latest vulcanization technology and high-performance rubber overall rubber coating, which is tightly coated, accurate in geometric dimensions, reliable in sealing and has a long service life.

2. Light weight: The valve body is made of ductile iron, which can reduce the weight by about 25% compared with ordinary gate valves, and is very convenient for installation and maintenance; the maximum opening height of the gate valve is generally 60mm~280mm, and it can also be installed on demand in places with small spaces.

3. Three "O" seals: The valve stem seal uses an O-ring seal, which has low friction, light weight and no water leakage.

Main performance parameters

|

Product Name: |

Rising Stem gate valve |

Material: |

Ductile Iron,WCB,SS |

|

Operation: |

Manual, worm gear, pneumatic, electric |

Connection: |

Flange |

|

Type: |

Wedge |

Seal: |

resilient,metal seat |

|

Pressure: |

0.1-1.6Mpa |

Size: |

DN40-600 |

Main Dimensions

|

SIZE |

D |

D1 |

L |

n-d |

||||||||||||

|

DN(mm) |

in |

10 |

16 |

25 |

150LB |

10 |

16 |

25 |

150LB |

DIN |

BS |

ASME |

10 |

16 |

25 |

150LB |

|

50 |

2 |

165 |

150 |

110 |

120.7 |

150 |

178 |

177.8 |

4-19 |

4-19 |

4-19 |

|||||

|

65 |

2.5 |

185 |

180 |

125 |

139.7 |

170 |

190 |

190.5 |

4-19 |

8-19 |

4-19 |

|||||

|

80 |

3 |

200 |

190 |

145 |

152.4 |

180 |

203 |

203.2 |

8-19 |

8-19 |

4-19 |

|||||

|

100 |

4 |

220 |

220 |

235 |

230 |

180 |

180 |

190 |

190.5 |

190 |

229 |

228.6 |

8-19 |

8-22 |

8-19 |

|

|

125 |

5 |

250 |

250 |

270 |

255 |

210 |

210 |

220 |

215.9 |

200 |

254 |

254 |

8-19 |

8-26 |

8-22 |

|

|

150 |

6 |

285 |

285 |

300 |

280 |

240 |

240 |

250 |

241.3 |

210 |

267 |

266.7 |

8-23 |

8-26 |

8-22 |

|

|

200 |

8 |

340 |

340 |

360 |

345 |

295 |

295 |

310 |

298.5 |

230 |

292 |

292.1 |

8-23 |

12-23 |

12-26 |

8-22 |

|

250 |

10 |

405 |

405 |

425 |

405 |

350 |

355 |

370 |

362 |

250 |

330 |

330.2 |

12-23 |

12-28 |

12-30 |

12-26 |

|

300 |

12 |

460 |

460 |

485 |

485 |

400 |

410 |

430 |

431.8 |

270 |

356 |

355.6 |

12-23 |

12-28 |

16-30 |

12-26 |

|

350 |

14 |

520 |

520 |

555 |

535 |

460 |

470 |

490 |

476.3 |

290 |

381 |

381 |

16-23 |

16-28 |

16-33 |

16-29 |

|

400 |

16 |

580 |

580 |

620 |

595 |

515 |

525 |

550 |

539.8 |

310 |

406 |

406 |

16-28 |

16-31 |

16-36 |

16-29 |

|

450 |

18 |

640 |

640 |

|

635 |

565 |

585 |

|

577.9 |

330 |

432 |

432 |

20-28 |

20-31 |

|

16-32 |

|

500 |

20 |

715 |

715 |

|

700 |

620 |

650 |

|

635 |

350 |

457 |

457.2 |

20-28 |

20-31 |

|

20-32 |

|

600 |

24 |

840 |

840 |

|

815 |

725 |

770 |

|

749.3 |

390 |

508 |

508 |

20-31 |

20-38 |

|

20-35 |

Parameter

|

Nominal pressure |

Nominal pressure |

Test pressure |

Working Temperature |

||

|

pn(MPa) |

DN(mm) |

Seal |

Shell |

||

|

1.0 |

40-600 |

1.1 |

1.5 |

≤200℃ |

water, steam, oil |

|

1.6 |

1.76 |

2.4 |

|||

|

2.5 |

2.75 |

3.8 |

≤100℃ |

oil, gas |

|